The power of first impressions for your brand cannot be overstated. You’ve probably come across ready-to-ship tin boxes, but have you used custom tin boxes? Beyond their aesthetic appeal, durability, and environmental friendliness, the biggest reason businesses choose tin boxes is their ease of customization. Custom tin boxes make your products stand out on the shelf and increase your brand’s visibility.

You can personalize tin boxes to your exact specifications regarding shape, size, embossing, and surface printing. The malleability of tin allows for numerous designs, giving your products that high-end, eye-catching appearance. This article will explain the various processes of customizing a tin box from start to finish, so your business can make the most of this versatile packaging option.

Customizing your tin box involves applying personalized designs, graphics, and messages. It is a detailed and creative process that requires collaboration with your manufacturer. The goal is to transform simple tinplate sheets into beautifully functional packaging for your business. We’ll break down the customization process into three steps.

Long before any physical tin box design takes shape, you must first lay a foundation of ideas that resonate with your brand. This phase involves several steps to ensure your final product aligns with your brand identity and meets your business objectives. During the conceptualization stage, companies may work with a tin box packaging consultant or an in-house design and engineering team to develop the right design for their needs.

Every design starts with an idea. The conceptualization phase is a brainstorming phase where you develop innovative tin design ideas that can be brought to life with customization. Here are the major things to consider in this phase:

Your tin box packaging should reflect your brand identity. It’s an extension of your brand and must feature your brand colors, styles, and fonts. Customers should have a feel for what your company entails when they see it. So, let your tin box designs project a vintage, premium quality.

At the end of this phase, you should have successfully conceptualized and created preliminary sketches of your tin box designs. From here, you can involve your manufacturer to bring your vision to life.

The customization phase is where your tin box begins to take shape. You’ll work closely with your manufacturer to bring your design vision to life. The good news is that you can customize just about any part of your tin box. Let’s explore the various options you have:

One massive benefit of tin is its malleability. Thanks to this, you can create custom tins in virtually any imaginable way. At Tengda, our staff employs various techniques to transform your tin ideas into beautiful containers. We produce round tins, square cans, rectangular cans, oval tins, heart-shaped tins, tree-shaped metal tins, book-shaped tin cans, bus-shaped tins, truck-shaped tins etc. Less popular shapes may be more expensive due to the need for extra tooling and specialized molds.

When choosing the right tin shape with your manufacturer, consider:

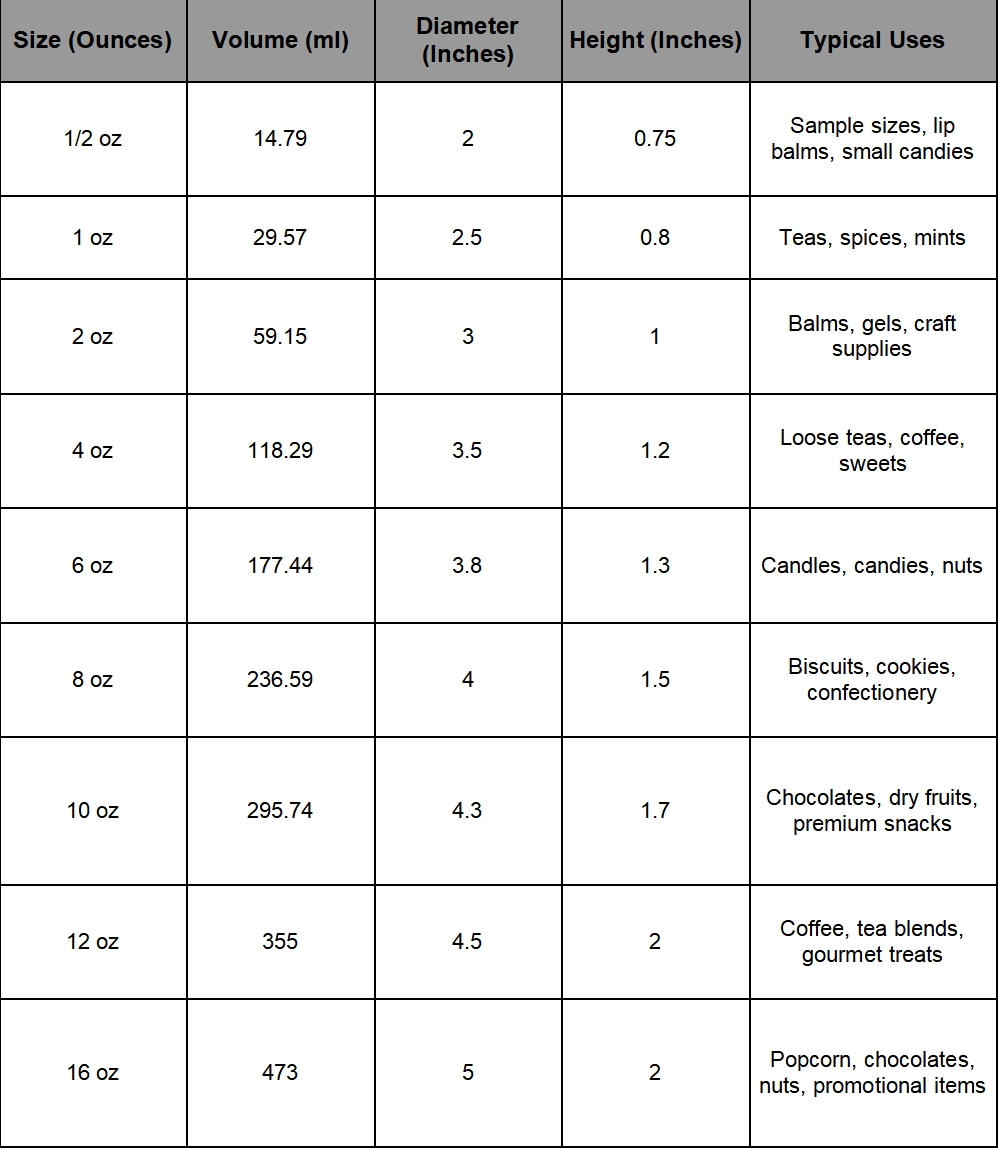

Next, we discuss the size of your box. Generally, the dimensions of tin boxes should resonate with the nature and volume of the product they’re meant to contain. Granular spices, for example, may benefit from smaller tins to ensure compactness and reduced air space, whereas lotions and balms may need larger tins.

When trying to find a size, we consider the product to be housed, the storage and reusability goals, and the ease of use for the consumer. If in doubt, always opt for a slightly larger size to be safe.

Internal Dimensions: Measure your product accurately to ensure it fits snugly within the tin. This helps to prevent movement and damage during transportation. In your calculations, give allowances for additional materials, like liners, dividers, or protective wraps, that will be included inside the tin.

External Dimensions: External sizing should take into account storage, shelf space, and shipping logistics. Tins that stack well in shipping cartons minimize wasted space and shipping costs.

An ounce-based approach to tin box-sizing is practical for most businesses. Check the table below for a comparison chart for different tin sizes.

For more Size and Volume details, you can check this size file.

If your product size doesn’t fall within these categories, don’t worry. Tengda can create custom sizes tailored to your specific product dimensions. Whether you are looking for small tin boxes for candles, candy tins, customized biscuit tins, cosmetic containers, or larger-sized cookie jars and tea tins, everything is possible when designing your custom tins. No matter how unique the idea, we’ll be able to turn it into a beautiful container.

After selecting the shape and volume of your custom tins, it’s time to consider the closing mechanism you want to use. Specialty closures can draw extra attention to your product. Tengda offers numerous options for tin boxes with lids, including hinged lids, sliding lids, screw caps, see-through lids, and slipcovers. The choice depends on the product and the aesthetic you’re aiming for.

Many times, the shape of the tin box determines the appropriate closing mechanism. For example, sliding lids work best for rectangular tins, and screw-top lids are ideal for round tin boxes.

We also provide unique specialty closures like decorative metal snap lids, which add a premium, collectible touch. On request, all lids can be equipped with an EPE liner to help seal your tins more tightly.

Embossing and debossing are techniques used to create raised or recessed designs on the surface of tin cans. They are guaranteed to transform your plain tin container into an authentic art piece and make your product stand out. Opting for these techniques can give your metal tins a 3D tactile feel and appearance.

Embossing involves raising the design above the surface of the tin can. This technique is popular for limited edition tins that often end up on people’s selves as collectibles. It produces a raised impression by pressing the metal from the back or using a counter die. Embossing can be combined with full-color printing for an even more striking effect that catches the light.

Debossing, on the other hand, produces a sunken or lowered appearance by pressing the design into the tin can’s surface. This method produces a design tin box that is recessed below the surrounding surface by pushing the metal downward using a female die and a counter die.

High-quality raw materials go hand in hand with high-quality products. The raw materials commonly used for custom tin cans are tinplate smooth iron, tinplate ground iron or galvanized iron. All our tin containers are made of high-quality tin plates sourced from reputable suppliers. If you’re into food products, you can be confident that our tin raw materials fulfill the standards for food grade and environmental preservation.

Please check the Test Report on Melamine and the Test Report on BPA here.

If your tin box comes in contact with water frequently, you might need a design that does not rust easily. In such cases, Tengda uses tinplate with food grade coating oil, which effectively prevents rusting. Our first-grade tinplate also offers excellent malleability, avoiding issues like edge whitening on the tin box.

You can choose from several finishes to add to your tin box design’s visual appeal and depth. Beyond aesthetics, finishes also provide a protective layer against corrosion. Standard finishes used by Tengda include:

Gloss Varnish: This is the most popular choice for tin packaging. Gloss varnish creates a shiny, reflective finish that enhances the contrast and depth of colors, making them appear more vibrant and eye-catching.

Matte Varnish: A non-reflective finish that provides a softer, smoother, and textured premium look.

Spot varnish: Spot varnish is a clear coating applied to specific areas of the printed material to highlight or emphasize certain elements, such as text or graphics. Sometimes we combine it with gloss and matte varnishes to make logos or other patterns stand out.

Metallic Luster Effect: This finish gives your product a luxurious, shiny feel. The process involves coating the box’s exterior with a thin metal foil layer, like silver or gold.

Blasting Varnish: This creates a rough-touch feeling, adding a unique tactile element to the packaging.

These finishes can also be combined to create unique effects, such as a matte over gloss finish.

At this stage, our designers clearly understand your vision for the tin box. We provide initial effect drawings for your checking. Our graphic designers develop the visual elements such as the logo, brand color schemes, images, and typography.

Tengda creates detailed packaging effect drawings that depict the product size, box angles, and other processes to save time and cost. Then, we create a 3D design model. With this, you can easily predict the practicality of your tin box and decide whether to proceed with the design.

Four-colour printing

Four-colour printing using CMYK (cyan, magenta, yellow, black) four-colour dot overlay to replicate the required colour, belonging to the principle of subtractive colour method, which is the most conventional printing process, colour brightness is higher, less saturated, but prone to colour deviation.

spot colour printing

Spot colour printing uses a single colour ink other than yellow, magenta, cyan or black to reproduce the colour of the original.It belongs to the principle of colour mixing, by blending a single ink colour to present the desired effect. Spot-colour printing is fuller in colour, with fewer errors, but at a higher cost.

Hot Stamping Printing

Printing gold powder or foil on the surface of tinplate to produce a metallic lustre effect.

Relief Printing

Using a letterpress plate to transfer ink directly to the surface of the tinplate, often used to print simple patterns such as text and lines.

Silk-screen Printing

The ink is printed onto the surface of the tinplate by means of a mesh screen, which is suitable for printing thicker patterns.

Silk-screen printing is an affordable option for introducing limited edition or promotional items into the market. Businesses love it because it differentiates their products by adding colorful wrapping. It can be applied to small metal containers and large tin cans and is available in single-color or multi-color layouts.

We can accurately screen print multi-color designs directly onto large popcorn tins thanks to our Multicolor Micro Screen Printing Technology (MMPT). Whether you want to include your logo or a full-color picture, silk-screen printing makes it all possible.

Flexographic printing

Flexographic printing is the use of flexible printing plates, through the anilox rollers to transfer ink printing method, flexible printing plate of the graphic part of the raised, printing anilox rollers will be a certain thickness of the ink layer evenly coated in the graphic part of the printing plate, and then in the embossing cylinder under the action of the pressure of the ink layer of the graphic part of the transfer of the surface of the substrate, the formation of a clear picture of the graphic.

In addition, there are spraying, electroplating, water transfer printing and other processes, according to different packaging requirements to choose the appropriate printing process.

We encourage clients to consider the following:

Now, we move to the final phase of the customization process. The manufacturer solely handles this stage.

At Tengda, we pride ourselves on using advanced technology and skilled craftsmanship to produce high-quality tin boxes. We have fully automated lines to ensure consistency throughout production. Our production process goes like this:

Tengda knows how bad tin packaging can affect your business, so we go above and beyond to guarantee that our high-quality products can survive the rigors of shipping and handling.

Before mass production, we create DAS – Designed Approved Sample – a prototype sample of your tin box for you to assess. Based on your feedback, we will make the necessary revisions until the design meets all your requirements perfectly.

Every product manufactured in our warehouse undergoes rigorous quality control and testing to ensure durability, functionality, and aesthetic standards. Some of the tests include heat and cold tests, seal tests, and drop tests.

During these tests, we check for defects like worn-out paint, potholes, printing scratches, edge whitening, and concave points on the surface. Products that pass these tests are transferred to the packing workshop for final packaging, while defective products are removed from the production line and destroyed.

The post-customization phase ends with packing and shipping to our clients. We have almost dust-free workshops where finished components like lids, ends, and bodies of tin boxes are cleaned with medical-grade alcohol to ensure hygiene and suitability to package any product. Then, all components will be assembled and packaged with multi-layer protection to ensure our tin containers are ready for use when you receive them.

If you have concerns about the transportation of your goods, you can consult Tengda. We offer efficient freight logistics services to deliver your products safely anywhere in the world at affordable prices.

Creating custom tin boxes can be a significant investment, but there are ways to manage expenses without compromising quality. Tengda’s in-house manufacturing process ensures our custom tin boxes are extra affordable. Here are some strategies to help you stay within your budget:

At Tengda, we believe your great product deserves even greater packaging. Your packaging should tell your brand’s story at a glance, and working with our professional designers ensures those lovely designs in your head come out looking way better than you imagined.

Tengda is the top choice for many of the world’s leading companies. We pride ourselves on offering unbeatable prices, fast production times, and excellent quality assurance. Our extensive production line covers various custom metal tin boxes wholesale, from small lip balm tins, candle tins, tea containers, custom tin lunch boxes, personalized biscuit tins, and holiday tin boxes for cookies, to large popcorn tins, personalized baking tins, clear cans, and everything in between. Here’s why thousands of businesses choose Tengda for their custom tin boxes needs.

With over 35 years of experience in the industry, our integrated in-house manufacturing process ensures that every step, from artwork processing through printing to production, is handled under one roof.

We have more than 3000 existing tooling/molds, which saves you a lot of money and ensures a swift production process. Our comprehensive approach allows us to maintain strict quality control, reduce production costs, offer competitive pricing, and ensure fast lead times.

Low budget? no problem, come to Tengda. Your packaging can be beautiful and still very affordable. Since you deal directly with us, there’s no middleman, reducing the cost of your custom tins by at least 20% compared to normal prices.

When you see a Tengda-manufactured tin can, you know it’s Tengda. Why? Because of our superior printing techniques. You need a manufacturer with state-of-the-art printing equipment, eco-friendly inks, and experienced printing engineers for a successful printing process. Tengda is one of China’s few tin container companies with an on-premises silk screen department, guaranteeing faster turnaround times and enhanced quality assurance.

Our expert team will recommend the ideal printing enhancements to make your custom tin irresistible on shelves. With our advanced printing technology, your tins will maintain their vibrant appearance for years, with no angle turning white after use. Your tin containers become a work of art when you use Tengda.

With a high productivity rate of 2 million pieces per month in our 6 automatic production lines and excellent workmanship, we guarantee timely and efficient fulfillment of your custom needs. Your order will be ready within a few weeks.

When quality assurance and control matter, you can always count on Tengda. As an ISO-9001-certified manufacturer, we uphold the highest quality and safety standards. We are licensed to produce all forms of tins, including food contact packaging. Our certified temperature tests, seal, and drop testing protocols eliminate performance uncertainty.

We offer various specialty finishes to add flair to your custom tins. We have whatever finishes you require, from embossing to gloss, matte, spot varnishing, and metallic luster effects.

We use only the finest raw materials in our production process. Our tin boxes are made from high-quality tinplate sourced from reputable suppliers and meet environmental protection and food-grade standards.

Tengda is one of the largest wholesale suppliers of custom tin cans globally. We offer efficient freight logistics services to deliver your goods safely and quickly anywhere in the world. Our reliable shipping solutions ensure that your products reach their destination in perfect condition.

Tengda goes above and beyond to provide exceptional value for our clients. Expect some of the following extra benefits:

Tengda prioritizes customer satisfaction. Always. We work closely with you throughout the entire process, from initial consultation to final delivery, to ensure that your needs are met and your expectations exceeded. Whatever you need, whenever you need it, our dedicated customer support team is always available to assist you.

Packaging quality reflects product quality in the eyes of consumers and significantly influences their buying decisions. Choosing Tengda as your personalized tin box manufacturer means partnering with a company dedicated to quality, innovation, and customer satisfaction. Let us provide you with a truly out-of-the-box experience. Contact us today.

There you have it—a step-by-step guide to customizing tin cans from start to finish. If you’re unsure where to begin, visit our Tins Catalog 2026 to see the various tin styles we offer. Select a product to view details, and contact us to help you get your customization project off the ground. We’re excited to bring your project vision to life!