Introduction

In the realm of custom packaging, the quest to transform imaginative ideas into tangible products is a journey filled with innovation, technical challenges, and creative problem-solving. This story begins with a simple yet unusual request, a testament to the limitless possibilities in the world of custom tin box manufacturing.

The Genesis of an Idea

It was a typical afternoon in the bustling corridors of our manufacturing facility when a message from Frank, a long-time client and innovator, popped up on my WeChat. Accompanying his text were photos of a robust and imposing Citroen truck. Confused, I promptly called him, half-expecting him to announce his venture into the automobile industry. Instead, Frank unveiled his vision: to create a tin box in the exact shape of this truck. His request, though unconventional, sparked a wave of excitement. The challenge was not just to create a tin box, but to encapsulate the essence of a Citroen truck in miniature form.

Understanding the Vision

Frank’s vision was clear: he wanted a tin box that was not merely a container but a representation of the Citroen truck’s distinctive design and robustness. This project was not just about aesthetics; it was about embodying the spirit of the truck in a functional, tangible product. The conversation with Frank was not just a briefing; it was a brainstorming session where ideas flowed, and possibilities were explored.

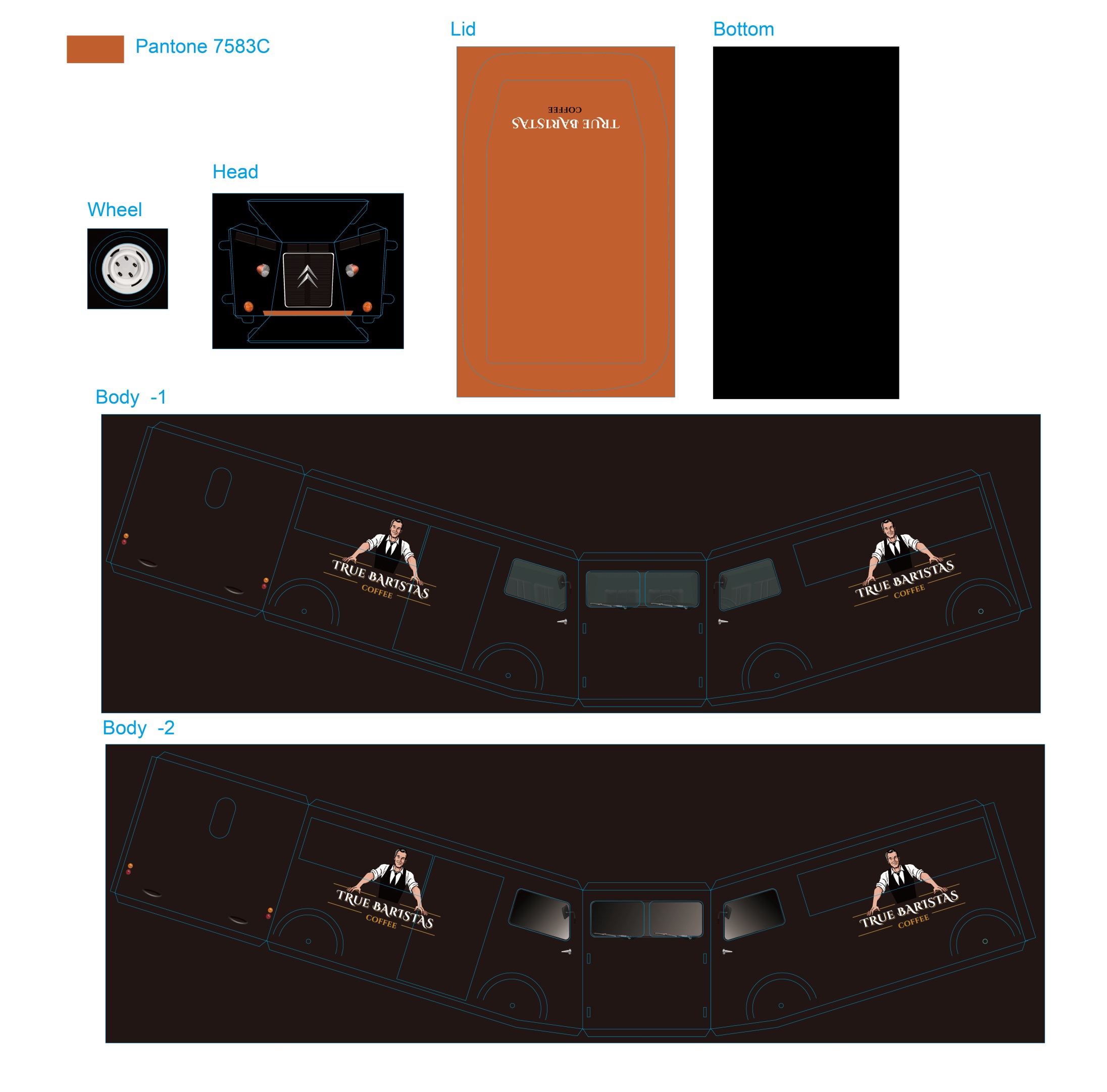

Step 1: Artwork and Design Visualization

Conceptualization

Our design team, a group of skilled artists and engineers, began the process of transforming Frank’s vision into a viable design. This stage involved numerous consultations, sketches, and digital renderings. The goal was to capture the truck’s dynamic lines, its imposing structure, and its unique character.

Design Challenges

One of the primary challenges was scaling down the truck’s design to fit a tin box while retaining its distinctive features. The team had to consider the proportions, the detailing, and how these elements would translate onto a smaller, three-dimensional object.

Finalizing the Design

After several iterations and feedback sessions with Frank, the final design was a masterpiece of miniature engineering. It was a perfect amalgamation of the truck’s robustness and the elegance of a tin box. The design was not only an artistic representation but also a technical blueprint for the subsequent stages of production.

Step 2: Mold Creation

Crafting the Mold

The transition from design to production began with the creation of the mold. This stage was crucial, as the mold would dictate the precision and quality of the final product. Our tooling department, equipped with advanced technology and seasoned artisans, took on this task.

Technical Precision

Creating a mold for such a unique design required meticulous attention to detail. Every curve, angle, and line of the truck had to be accurately represented in the mold. This process involved state-of-the-art computer-aided design (CAD) and computer-aided manufacturing (CAM) technology, ensuring every detail was captured.

Quality Checks

Before finalizing the mold, it underwent a series of quality checks. These checks were crucial to ensure that the mold met our stringent standards and was capable of producing a tin box that would be a true representation of the Citroen truck.

Step 3: Printed Tinplate Preparation

The Art of Printing

With the mold ready, the next step was the printing of the tinplate. This process was not just about transferring the design onto the metal; it was about bringing the design to life. The colors, textures, and finishes had to perfectly match the truck’s aesthetics.

Challenges in Printing

One of the challenges in this phase was ensuring color fidelity and detail precision. The printing process had to accurately reproduce the intricate details of the truck, from its iconic grille to the subtle contours of its body.

Ensuring Perfection

After several trials and adjustments, the printed tinplate was ready. It was a vibrant and accurate representation of the Citroen truck, ready to be shaped and assembled.

Step 4: Assembly Line Activation

The Assembly Process

The assembly of the tin boxes was a ballet of precision and efficiency. Our production line, equipped with the latest machinery and skilled workers, began the meticulous process of shaping, cutting, and assembling the tin boxes.

Overcoming Challenges

The unique shape of the truck posed several assembly challenges. Each tin box had to be assembled with precision, ensuring that the final product was not only aesthetically pleasing but also structurally sound.

The Final Product

As the assembly line hummed with activity, the tin boxes began to take shape. Each box was a miniature replica of the Citroen truck, with every detail carefully crafted and assembled. The final product was not just a tin box; it was a work of art.

Step 5: Sample Approval and Trial Order

Pre-Production Samples (PPS)

Once the assembly was complete, we sent a batch of pre-production samples (PPS) to Frank for his final approval. This step was crucial to ensure that the product met his expectations and our quality standards.

Feedback and Approval

Frank’s response was overwhelmingly positive. The samples exceeded his expectations, capturing the essence of the Citroen truck in every detail. His approval was the green light we needed to proceed with a larger production run.

The Trial Order

Confident in the quality of our product, we commenced a trial order of 2,000 pieces. This initial batch was not just a test of our production capabilities but also a validation of our ability to turn a creative vision into reality.

Conclusion: A Symphony of Creativity and Engineering

This project with Frank was more than just a manufacturing task; it was a journey of creative engineering, a testament to our team’s ability to transform a concept into a tangible product. The Citroen truck tin box was not just a container; it was a symbol of innovation, craftsmanship, and attention to detail.

Beyond the Ordinary

This project exemplified our commitment to going beyond the ordinary, to taking on challenges that push the boundaries of what is possible in custom tin box manufacturing. It was a showcase of our ability to blend art and engineering, creativity and precision.

A Call to Action

If you, like Frank, have a vision for a unique tin box, we are here to make it a reality. Our team is ready to take on your most challenging ideas and transform them into exceptional products. Whether it’s a tin box shaped like a vehicle, a building, or any other object, we have the expertise and the technology to bring your vision to life.

Let’s Talk

Reach out to us, and let’s embark on a journey of creative collaboration. Let’s transform your ideas into tangible products that not only serve as functional packaging but also as a statement of your brand’s creativity and innovation.

For inquiries and collaborations, please contact us. Let’s make the extraordinary happen.